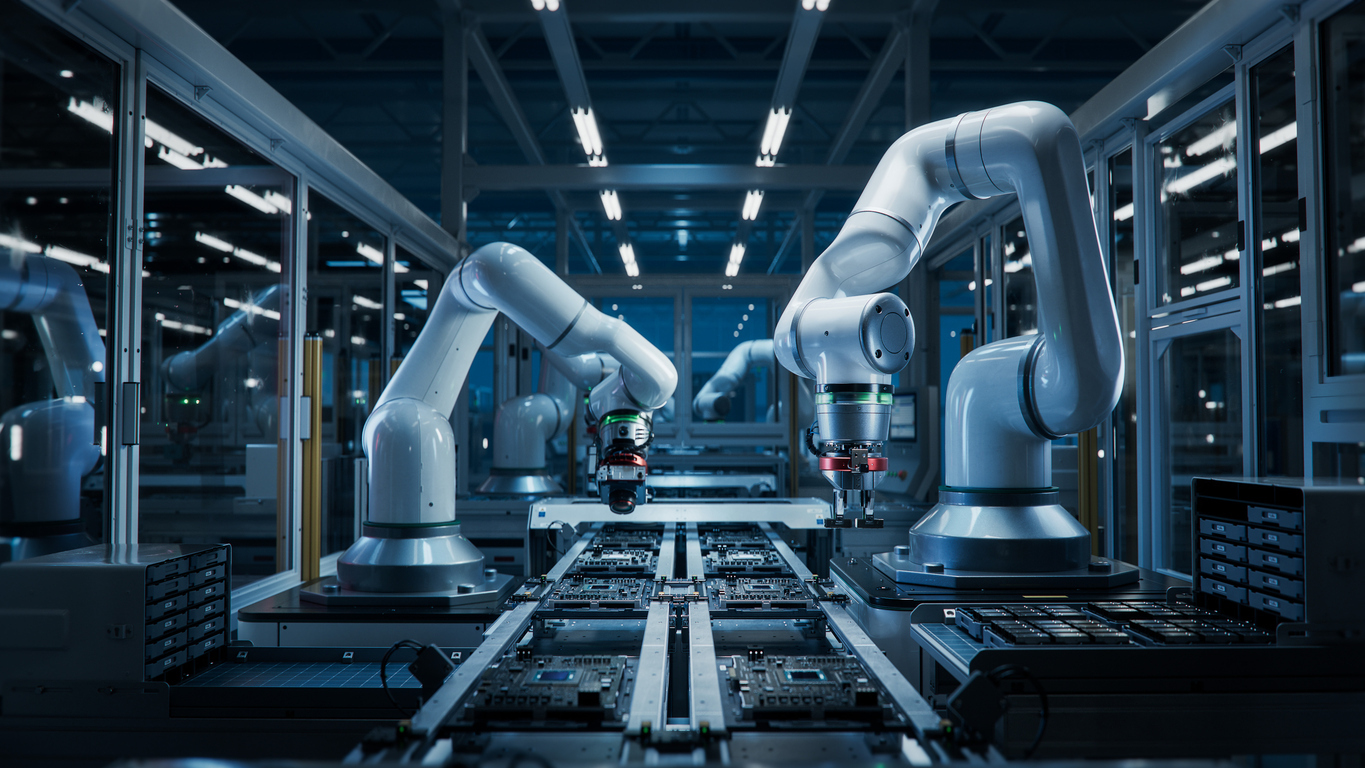

Driving Motion: High-Power Analog Amplifiers in Robotic Applications

High-power analog electronics are essential in modern robotics, supporting motor drivers, power supplies, and analog signal conditioning. From controlling high-current motors to regulating multiple voltage rails, these circuits enable reliable physical motion and system performance.

Low power digital systems, like microcontrollers and FPGAs, are responsible for handling logic, computation, and control algorithms. However, they are not capable of directly driving motors, actuators, or power systems because those types of circuits require much higher voltages and currents than digital circuits can provide.

This creates an opportunity for high-power analog electronics to provide support. High power op amps serve as the interface between low-power digital control signals and the high-power mechanical requirements of an assembly that performs physical actions.

Analog power electronics are applicable in multiple respects within a robotic system.

Analog Motor Drive and Control

Robots use electric motors to provide mechanical movement necessary to complete a given task. These motors can be of various configurations like DC, brushless DC, or AC servo motors, all of which require substantial current to operate. This level of current is normally controlled by a high-power analog op amp circuit. Motor drivers take low-voltage logic signals, like those from a microcontroller, and amplify them to deliver tens or hundreds of volts and amps. These circuits are designed with power transistor outputs (MOSFETs, IGBTs, SiCs) and analog feedback loops to provide motor regulation such as speed control, torque control, and position control.

For example, an industrial assembly robot arm might require a 48V, 20A motor driver configured in a constant current configuration that keeps torque stable by providing a constant 20A even when load changes. In this case, a high-power analog op amp would be ideal to create such a circuit and provide a constant 20A regardless of load magnitude.

Power Supplies and Converters

Since robots can often contain multiple internal systems that have different voltage requirements, they may need multiple voltage rails to support all subsystems:

- 5 V or 3.3 V for digital logic

- 12 V for sensors and controllers

- 24–60 V (or more) for motors and actuators

High-power analog electronics can be designed to diversify the available voltage levels in a system by acting as either switch-mode power supplies (SMPS) or DC–DC converters. These circuits are analog in nature as they continuously regulate voltage and current with analog feedback architecture and high-power output stage transistors.

Sensor Interfaces and Analog Signal Conditioning

Robotics function based on the response of a multitude of sensors that may exist throughout their system, with complexity varying from one sensor to hundreds of sensors. Many of these sensors output analog signals that require amplification to propagate through the system completely and reach the necessary interface. Some examples of sensors on board a robotic system could include:

- Force/torque sensors

- Strain gauges

- Accelerometers and gyros (in analog form)

- Position encoders (analog sine/cosine outputs)

- Current sensors

These analog output signals are often small (on the order of millivolts) and can also be noisy. Because of this, the signal can often require filtering, amplification, and perhaps even conversion from analog to digital to be correctly interpreted.

In demanding industrial robotics applications, component selection becomes critical when high reliability and performance are required.

Apex Microtechnology high-current operational amplifiers, high-voltage operational amplifiers, and PWM amplifiers are a leading choice for motor control, piezo drive, and current control applications across the industrial OEM market. This product family of power op amps, PWM amplifiers, and precision voltage references provides cost-effective, off-the-shelf solutions that deliver maximum performance.

To read more on robotics and the applications supported by apex, visit our hi-rel industrial applications page.

-Apex Microtechnology